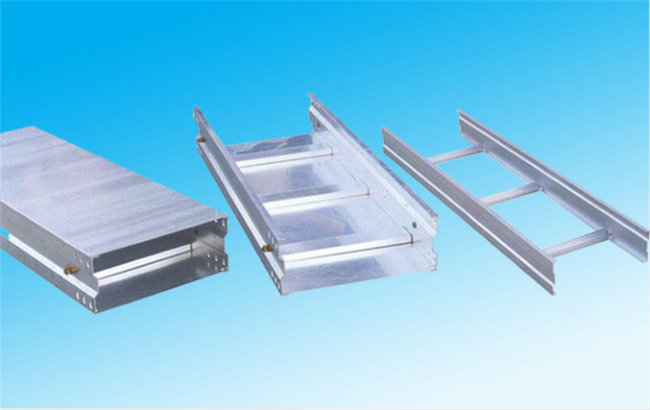

Aluminum alloy bridge has the characteristics of beautiful appearance, simple structure, unique style, large load capacity and light weight. After anodizing on the surface of aluminum alloy cable tray, it is not only anti-corrosion, but also anti electromagnetic interference, especially anti shielding interference, which can not be replaced by steel cable tray. Aluminum alloy bridge has important practical value in modern industry, modern national defense and modern high technology.

General term for aluminum based alloys. The main alloy elements are copper, silicon, magnesium, zinc and manganese, and the secondary alloy elements are nickel, iron, titanium, chromium, lithium, etc.

Aluminum alloy has low density but high strength. It is close to or higher than high-quality steel and has good plasticity. It can be processed into various profiles. It has excellent conductivity, thermal conductivity and corrosion resistance. It is widely used in industry, and its usage is only second to that of steel.

Aluminum alloy is divided into two categories: cast aluminum alloy, which is used in as cast state; Deformed aluminum alloy can withstand pressure processing, and its mechanical properties are higher than those of as cast. It can be processed into aluminum alloy materials of various shapes and specifications. It is mainly used for manufacturing aviation equipment, daily necessities, building doors and windows, etc.

Aluminum alloy cable tray has the characteristics of beautiful appearance, simple structure, unique style, large load capacity and light weight. After anodizing on the surface of aluminum alloy cable tray, it is not only anti-corrosion, but also anti electromagnetic interference, especially anti shielding interference, which can not be replaced by steel cable tray. Aluminum alloy bridge has important practical value in modern industry, modern national defense and modern high technology.

Excellent high corrosion resistance, suitable for power plants, chemical, petrochemical and other fields, especially for places with high corrosion environment. The extruded ladder edge and rung make the appearance of the bridge bright and clean. The reasonable processing technology and connection mode make the installation of the bridge convenient. Among them, the large span disc straight through can meet the bearing capacity of 6m. Aluminum alloy disc base plate can adopt flat plate structure or convex stamping structure as required.

Some aluminum alloys can be heat treated to obtain good mechanical properties, physical properties and corrosion resistance.

Cast aluminum alloy can be divided into aluminum silicon alloy, aluminum copper alloy, aluminum magnesium alloy, aluminum zinc alloy and aluminum rare earth alloy according to chemical composition. Among them, aluminum silicon alloy also has simple aluminum silicon alloy (unable to be strengthened by heat treatment, low mechanical properties and good casting properties), and special aluminum silicon alloy (heat treatment can be strengthened, high mechanical properties and good casting properties).

中文(簡(jiǎn)體)

中文(簡(jiǎn)體)